Guest Blog by: Charlie Morgan

Off-site construction can mean a lot of things for a vast array of structures, and manufactured homes are set up in very similar ways to other off-site homes. Manufactured homes, as defined by the Department of Housing and Urban Development, have changed tremendously over the last 50 years, but the basic installation process is straightforward and only varies slightly among the different manufacturers.

To begin, the first section of the home is positioned close to where it is to be placed with the delivery truck or a machine. The next section is positioned close to the other, but the room is left down the middle to remove shipping material and scatter pier materials, using a variety of machines or manual tools to position the home exactly where it needs to go.

Most homes are lifted at the tongue of the frame with either the delivery truck or a heavy machine. The two most popular machines in this category are a House Tug and a Remote Trax. Both are very useful for difficult deliveries as well as being remarkably powerful.

Towards the end of the frame where the axles are located, contractors either use jacks or another tracked machine to lift the section to be set.

The machine for this application is many times, either a Platypus (pictured) or a Translift. These long, low-lying machines are very efficient and especially useful when a house is on a sloped site, where one end may go higher than the front.

Once the house is positioned exactly where it goes and lifted to final floor height, the contractor and their team removes shipping material, take off the axles and tires (which will be recycled and used on another home) from the frame, and begins constructing the piers under the home.

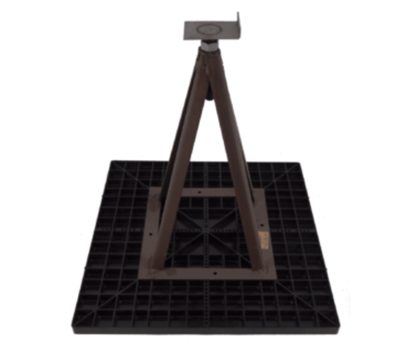

In most cases, piers are built with dry-stacked concrete blocks, capped with hardwood boards or solid concrete blocks, and topped with hardwood shims. In other areas of the country where seismic movement or flooding is to be expected, steel piers (pictured) or treated wood pylons are used to satisfy local regulations.

To level steel piers or block piers, a set-up professional will use a water level. Water levels are extremely accurate and produce piers that are leveled within ⅛” of each other when used properly. It is crucial to get piers within this tight tolerance to equally distribute weight on all piers for the home to perform as the manufacturer intended and provide the best experience for the homeowner.

Once the sections are aligned with each other and resting on piers, the contractor will go about mechanically attaching the houses together. Where two sections meet is called the marriage line, and this line extends from the floor, up the walls, and across the ceiling.

For the floor, the two sections of the house are joined using large lag bolts through one-floor joist and ceiling header to its opposite mate. Most homes will require a lag bolt at every 18-24” to meet local regulations. During this process, the floor is also leveled to make sure one section is flush with the other.

Once the floor is attached, the installation crew will begin working on connecting the marriage line along the ceiling or roof. Different manufacturers will require various ways of making this union. Some prescribe connecting the top of the trusses with metal straps; others require structural bolts along the header or ridge line. In every case, this connection process is to line up the main structure of the house, preventing the house sections from moving laterally.

Once the connection is made, the roof is finished just like a traditional site-built house with a shingle or metal ridge cap. The final steps for attaching the two halves involve joining the ends of the house, called the end walls, with either structural bolts or lag bolts.

Lastly, the final step of satisfying the setup process is to anchor the house to the foundation. The type of anchoring system is determined by a number of factors but is mainly dependent on the addresses’ Wind Zone classification and soil conditions around the home site.

Anchors are driven (or screwed) into the ground and use heavy-duty metal straps to attach (anchor) the house permanently to the ground. In recent years, alternative innovative anchoring systems have been permitted, but they all prevent lift and movement,

When the above steps are completed, the initial setup is complete. At this point, the contractor simply has to finish up the trim, siding, utility hookups, and other tasks to make it a family-ready home. After the specified, engineered setup process is complete, the manufactured home will be incredibly resilient and structurally sound for decades to come.

*Mating is a term used in the manufactured housing industry when joining 2 sides of a home. The centerline of the two halves is called a “mate line.” Therefore when the home sections are put together, they are “mated,” and the process of doing this is referred to as “mating.”

Charlie Morgan

Charlie Morgan is a site construction professional in Knoxville, Tennessee. He is the third generation of a family committed to mastering and advancing manufactured and modular home site construction and actively seeks to educate prospective home buyers on the nuts and bolts of making a house a home.